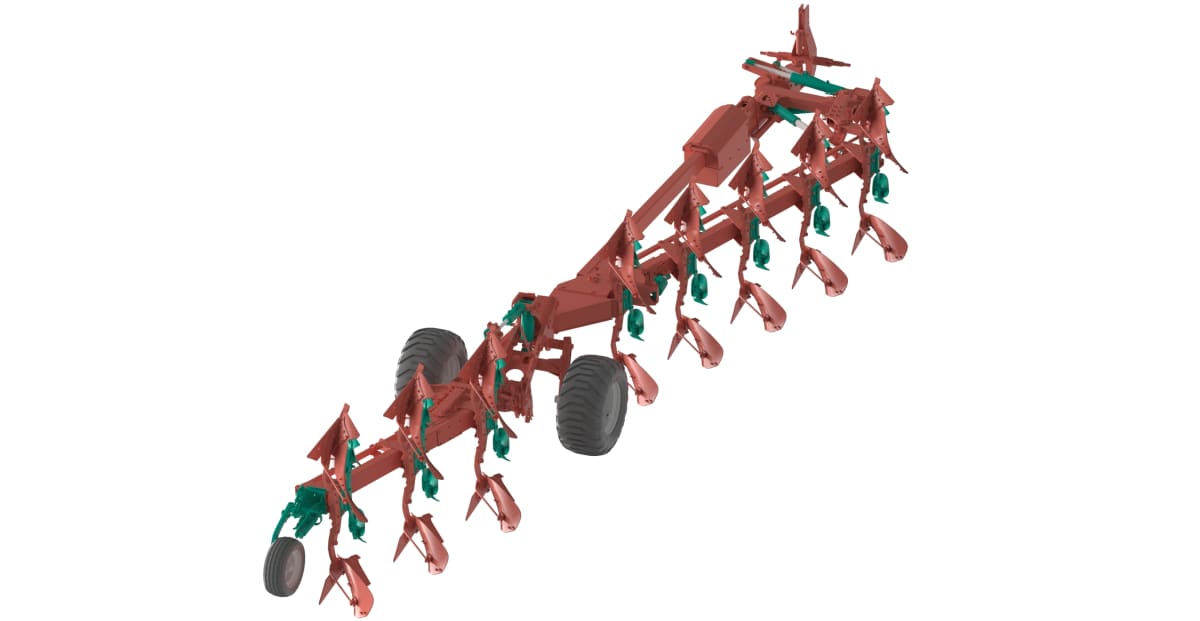

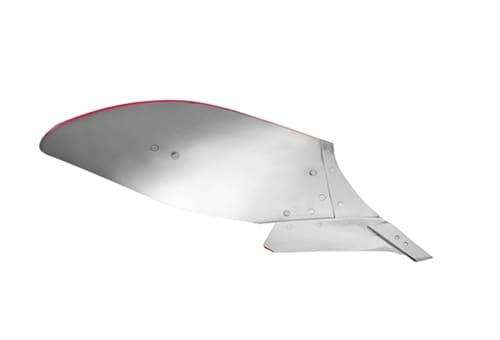

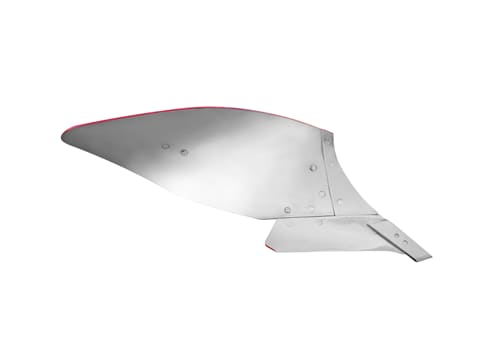

Kverneland RW

Efficient, flexible, easy to operate

"3 ploughs in 1" for high capacity ploughing In-Furrow & On-Land Isobus and FURROWcontrol available 7 - 12 furrows

Highlights

Easy and safe to adjust and to operate In-Furrow and/or On-Land Stable while turning and in transport Use either front or rear ploughs or together Re-consolidation: Packomat availableDescription

The Kverneland RW and RW Variomat® are hearbolt leg protected. They consists of a robust semi-mounted plough in the front and a standard LD mounted reversible plough at the rear. “3 in 1 concept": depending on weather and soil conditions, either use the whole wagon plough or only the front or the rear plough. Likewise if 2 fields need to be ploughed simultaneously, the front and the rear ploughs can work in each field. Working width adjustments are either manual for the RW or hydraulic for the RW Variomat®. Even in hilly conditions a quality ploughing is guaranteed: the 3 point linkage of the center section ensures that the RW follows the ground at all times.

Highlights

- Easy and safe to adjust and to operate (ATS, Isobus, manual management with the addition of a valve controller or manual management via tractor control)

- FURROWcontrol for easy straight furrows is available for the Isobus RW Variomat®

- "In-Furrow" and/or "On-Land"

- Stable while turning and in transport

- Re-consolidation: Packomat available

Features

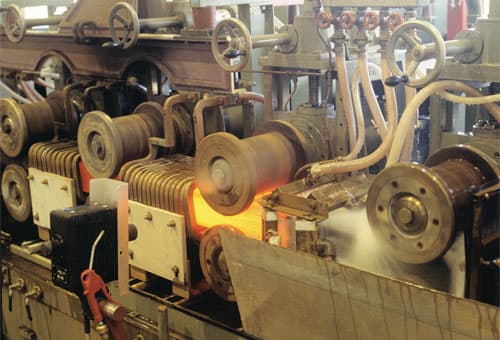

Importance of heat treatment

- The frame is an essential part of the plough construction. For Kverneland quality standards, a non heat treated part is a weak part!

- Kverneland frames are heat treated by induction twice. The temperature transfer to the steel is closely monitored. The frame gains 3 times as much strength. This unique Kverneland induction processes provides robustness and flexibility while ensuring an outstanding durability.

Stronger but not heavier

- For the equivalent Kverneland robustness, competitors would use more steel in thickness or in dimensions, therefore producing a heavier frame.

- Heavier frame impacts negatively pulling forces, wearing of parts, lifting capacities, tractor life time, and fuel consumption.

Long lasting

- Weldings are also a critical weakness for a plough frame. Kverneland frames are supplied as one sole part, no welding!

Frame availability

- 120 x 200 mm 7-9 furrows

- 200 x 200 mm 10 and12 furrows

- 200 x 250 mm 12 and 14 furrows

- The “tail” of the plough is either a 200 or a 300 head stock EG/LB plough

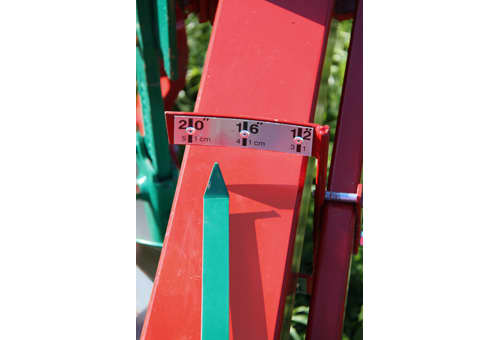

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

Excellent Ploughing Quality

They are renowned all over the world for their:

- excellent ploughing quality

- outstanding wear resistance

- low draft requirements

Bodies of a unique steel.

Kverneland Technology: 12 hours carburising heat treatment process for:

- optimum wear resistance (sharp as a diamond)

- the necessary flexibility to absorb impacts

Body No. 8 – “Universal body”

for light to heavy soils

good trash burial

easy pulling

Depth: 15 to 30 cm (6 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 9 – “Deep Universal body”

for heavier soils and deeper ploughing

well turned and packed furrows

easy pulling

Depth: 15 to 35 cm (6 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 28 – “Wide tyre body”

suits all soils; even heavier soils than body 8

very wide empty furrow for tractor wheels up to 710 mm

good turning and well packed

easy pulling

suitable for Depth: 12 to 30 cm ( 5 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 30 – “Finger body”

for sticky-stony soil and abrasive soils

good work in heavier soils

best crumbling effect

wide furrow bottom,

Depth: 20 to 35 cm (8 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 34 – Plastic mouldboard

Long and slim shape (similar to body 28)

For soils with high humus content without stones

Advised for tactors with large tyres

Easy pulling

Working depth: 12-35cm

Working width: 30-55cm

Landside / mouldboard: 40 degree

Body No. 38

universal body – easy to pull

for any soil conditions

recommended for tractors with large tyres

from deep to shallow ploughing

perfect turning of the furrow slice

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

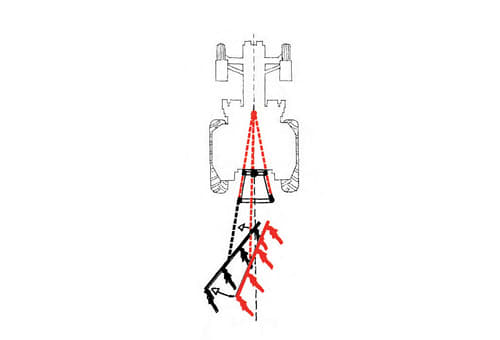

Unbeatable in stony conditions !

Kvernelands fully automatic non-stop Auto-Reset System is unbeatable when it comes to trouble-free ploughing in stony conditions. The clever multi-leaf spring system allows the plough legs to release over stones and other solid objects in a smooth and efficient manner. This avoids sudden jolts and possible damage. Once the obstruction is passed, the plough body automatically returns to the correct ploughing depth.

Safety compliance

With today's demands for higher output, both tractor and plough are expected to perform quicker than ever. This makes more arduous demands on the equipment, particularly on the safety systems designed to protect tractors, ploughs and drivers against the dangers encountered whenever the plough meets hidden obstructions in the ground. The Kverneland Auto-Reset system guaranties this safety high standars requirements.

Adaptable to varying soil conditions

Depending of the type of soil all Kverneland ploughs can be equipped with different leaf springs packages. For soft soils, a normal spring with 5 leaves is the best choice to obtain the perfect ploughing in stony conditions. Today, most Kverneland ploughs are delivered with the Heavy Duty springs package (HD) with 7 leaves. This will perform well in most conditions. If the soil is very hard and stony - a double leaf spring package is recommended.

Extra leaves when needed

The standard Auto-Reset system includes 7 Kverneland heat treated springs (640Kp).

For heavier to extreme soil conditions, extra leaf springs are added for up to 1400kp.

The leaves are easily fixed with one central bolt only.

Individual body release !

The Kverneland mechanical Auto-Reset system enables very plough body to release independently. A quality ploughing is therefore guaranteed.

Minimum wear and high second hand value

Kverneland's Auto-Reset System is a quite simple construction that withstands the punishing forces year in, year out, with a minimum of maintenance. Save time and money !

Moreover, the Kverneland auto-reset system guarantees a longer life to the plough. When hitting an obstacle, the pressure on the point, frame, plough parts, decreases. The stress on Kverneland ploughs is therefore reduced. Consequently, second hand Kverneland ploughs sell at a higher value than competitors ploughs.

*by using an Hydraulic system, pressure would increase

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

Precision Farming

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

IsoMatch Tellus GO+ is especially developed for controlling the machine in a simple way. The farmer is in full control of the machine in exactly the way he wants. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch. Controlling the implement has never been so easy.

This can be you your first step into Precision Farming

IsoMatch Tellus GO+ makes it easy to control any ISOBUS machine from your tractor cab. IsoMatch GEOCONTROL enables you to achieve higher yields, lower costs and do your work with less hassle. This licence key is divided in two parts, Section Control and Variable Rate Control, which are available from the IsoMatch Shop. Now you can buy the specific functionality that you need.

Technical specifications

Technical specifications

Download brochure| Model | RW | RW V | RW V | |

|---|---|---|---|---|

| Interbody clearance cm | 100 | 100 | 115 | |

| Type of beam | Shearbolt | Shearbolt | Shearbolt | |

| Working width cm | 35-50 | 35-50 | 35-50 | |

| Underbeam clearance cm | 70/80 | 70/80 | 70/80 | |

| No. of furrows | 7-12 | 7-12 | 7-10 | |

| Weight (Kg), 7 furrows | 4695 | 4800 | 4835 | |

| Weight (Kg), 8 furrows | 5130 | 5250 | 5290 | |

| Weight (Kg), 9 furrows | 5565 | 5700 | 5745 | |

| Weight (Kg), 10 furrows | 6050 | 6200 | 6250 | |

| Weight (Kg), 11 furrows | 6495 | 6660 | – | |

| Weight (Kg), 12 furrows | 6940 | 7120 | – | |

| Pulling req. (Hp), 7 furrows, from | 210 | 210 | 210 | |

| Pulling req. (Hp), 8 furrows, from | 240 | 240 | 240 | |

| Pulling req. (Hp), 9 furrows, from | 270 | 270 | 270 | |

| Pulling req. (Hp), 10 furrows, from | 300 | 300 | 300 | |

| Pulling req. (Hp), 11 furrows, from | 330 | 330 | – | |

| Pulling req. (Hp), 12 furrows, from | 360 | 360 | – |