Kverneland 6300 S VARIOMAT

Low operating cost and ideal weight transfer for high ploughing performance.

Versatile plough for high output performance New Generation of semi-mounted reversible ploughs 5 - 8 furrows

Highlights

Aero-profile high legs for best soil flow performance Quick central adjustments of skimmers Large rear wheel for optimized weight transfer Safe reversing and minimal headlands Vary-Width® - "On the move" furrow width adjustmentsDescription

The Kverneland 6300 S Variomat® is a New Generation of semi-mounted reversible ploughs, designed for large areas. It won the Machine of the Year award in the Tillage category in 2020. Fitted with the Auto-reset and the Variomat®, it adapts to varying soil types and conditions: Excellent manoeuvrability during work and transport. The largest rear mounted wheel on the market is rear fitted for the best weight transfer balance from the wheel to the tractor rear wheels. Consequently, the plough is stable, easy to pull even in wet conditions. Easy headlands with a small reversing radius. The low center of gravity of the plough ensures a safe transport

Highlights

- High aero-profile high legs for best soil flow performance

- Quick central adjustments of skimmers for the perfect ploughing

- Large rear wheel for optimized weight transfer: easy pulling, high quality ploughing

- Large wheel for best stability especially in wet conditions to limit sinking and soil compaction

- Robust construction: Cat III / IV, 200 x 200 mm main frame (no welding)

- Safe reversing and minimal headlands thanks to the robust turnover mechanism for an optimal angle

- Hydraulic or manual front furrow adjustment

- Soil re-consolidation: Kverneland Packer available

Features

Aero-profile legs

- Special design for best soil flow.

- 80 cm leg height to prevent potential blockage in heavy residues, manure, cover crops or when ploughing deeper.

- Robust legs: pre-shaped components limiting weldings.

- Low pulling requirement and hence fuel consumption thanks to low weight hollow legs.

Auto-reset system

- Unrivalled Kverneland mechanical leaf spring system for Non-stop ploughing.

- No Maintenance.

- Legs, plough and tractor lives are protected and lengthened.

- Quality ploughing: legs release independently one from another and come back to the correct position.

- Easy adjustment of releasing forces: unscrew 2 bolts to add or remove springs.

Leaf springs |

Release Pressure kN |

Standard Pack 6 leaf springs |

11,7 |

Standard Pack 6+1 leaf springs |

13,0 |

HD 7 leaf springs |

12,7 |

HD 7+1 leaf springs |

14,2 |

Extra HD 8 leaf springs |

15,3 |

Extra HD 8+1 leaf springs |

16,9 |

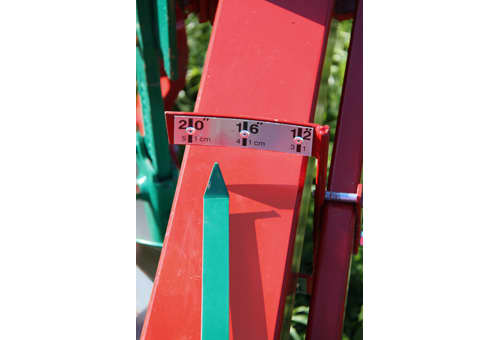

Smart skimmers adjustment

- Unique: central adjustment of skimmers working depth.

- Quick operations: right and left skimmers adjust simultaneously.

- High ploughing performance: the correct adjustment of skimmers contribute to a quality ploughing.

- Disc coulters also available: plain or notched (18”/45cm or 20”/50cm)

Importance of heat treatment

- The frame is an essential part of the plough construction. For Kverneland quality standards, a non heat treated part is a weak part!

- Kverneland frames are heat treated by induction twice. The temperature transfer to the steel is closely monitored. The frame gains 3 times as much strength. This unique Kverneland induction processes provides robustness and flexibility while ensuring an outstanding durability.

Stronger but not heavier

- For the equivalent Kverneland robustness, competitors would use more steel in thickness or in dimensions, therefore producing a heavier frame.

- Heavier frame impacts negatively pulling forces, wearing of parts, lifting capacities, tractor life time, and fuel consumption.

Long lasting

- Weldings are also a critical weakness for a plough frame. Kverneland frames are supplied as one sole part!

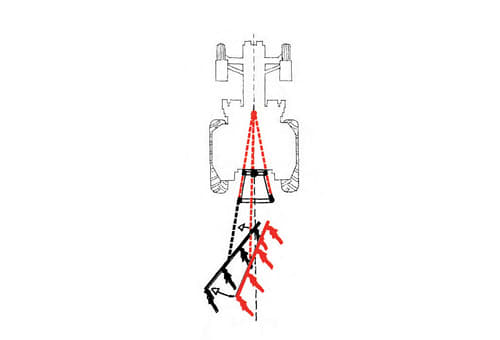

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

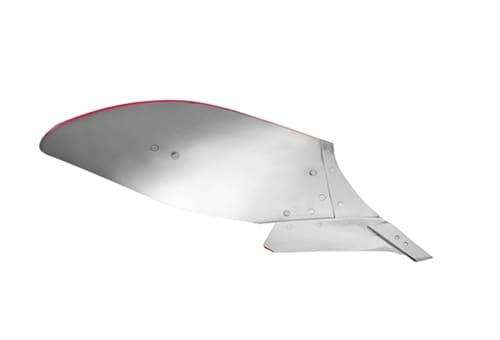

Excellent Ploughing Quality

They are renowned all over the world for their:

- excellent ploughing quality

- outstanding wear resistance

- low draft requirements

Bodies of a unique steel.

Kverneland Technology: 12 hours carburising heat treatment process for:

- optimum wear resistance (sharp as a diamond)

- the necessary flexibility to absorb impacts

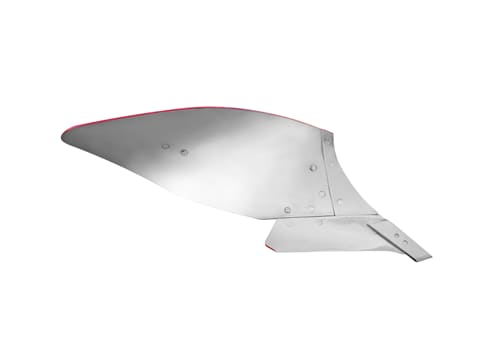

Body No. 8 – “Universal body”

for light to heavy soils

good trash burial

easy pulling

Depth: 15 to 30 cm (6 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 9 – “Deep Universal body”

for heavier soils and deeper ploughing

well turned and packed furrows

easy pulling

Depth: 15 to 35 cm (6 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 28 – “Wide tyre body”

suits all soils; even heavier soils than body 8

very wide empty furrow for tractor wheels up to 710 mm

good turning and well packed

easy pulling

suitable for Depth: 12 to 30 cm ( 5 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 30 – “Finger body”

for sticky-stony soil and abrasive soils

good work in heavier soils

best crumbling effect

wide furrow bottom,

Depth: 20 to 35 cm (8 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 34 – Plastic mouldboard

Long and slim shape (similar to body 28)

For soils with high humus content without stones

Advised for tactors with large tyres

Easy pulling

Working depth: 12-35cm

Working width: 30-55cm

Landside / mouldboard: 40 degree

Body No. 38

universal body – easy to pull

for any soil conditions

recommended for tractors with large tyres

from deep to shallow ploughing

perfect turning of the furrow slice

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

Technical specifications

Technical specifications

Download brochure| Model | 6300 S Variomat | 6300 S Variomat | |

|---|---|---|---|

| Interbody clearance cm | 100 | 115 | |

| Leg protections | Auto-reset | Auto-reset | |

| Working width cm | 35-55 | 35-55 | |

| Underbeam clearance cm | 80 | 80 | |

| No. of furrows | 6-8 | 5-7 | |

| Weight (Kg), 5 furrows | – | 3060 | |

| Weight (Kg), 6 furrows | 3340 | 3430 | |

| Weight (Kg), 7 furrows | 3720 | 3820 | |

| Weight (Kg), 8 furrows | 4100 | – | |

| Pulling req. (Hp), 5 furrows, from | – | 125 | |

| Pulling req. (Hp), 6 furrows, from | 150 | 150 | |

| Pulling req. (Hp), 7 furrows, from | 175 | 175 | |

| Pulling req. (Hp), 8 furrows, from | 200 | – |

Technical specifications

Technical specifications

Download brochureModel |

Interbody Clearance cm |

Underbeam clearance cm |

Working width cm |

No of furrows |

6300 S Variomat |

100 |

80 |

35 - 55 |

6 - 8 |

6300 S Variomat |

115 |

80 |

35 - 55 |

5 - 7 |