Kverneland 3300F

Excellent ground tracking and new level of operator comfort

Front mounted mower conditioners with ProLink suspension.

Highlights

ProLink suspension concept Flexible adaptation range of 670mm Transverse adaptation range of 24º. Maintenance-friendly design for operator comfort Self-adjusting swath doorsDescription

Kverneland 3300 F series, with SemiSwing or roller conditioner and working widths of 3.16 - 3.60m, brings new comfortable features to front mounted mower conditioners. It is the ideal combination of effective suspension concept for accurate cutting performance and new operator friendly features. It is designed around the ProLink suspension, an extremely responsive and durable concept. With its floating 3-dimensional suspension, it delivers excellent ground tracking for accurate cutting performance and great cutterbar protection.

Highlights

- ProLink suspension concept with three-dimensional ground tracking.

- Flexible adaptation range of 250mm downwards and 420mm upwards.

- Transverse adaptation range of 24º.

- Dual adjustment of conditioner plate for accurate setting of conditioning effect.

- Maintenance-friendly design with focus on operator comfort.

- Stubble height adjustment integrated into suspension for easy setting of cutting angle.

- New self-adjusting swath doors for easy and accurate setting of swath width.

Features

- ProLink 3-dimensional suspension concept for excellent ground tracking.

- Very responsive and durable suspension concept with two largely designed suspension spring for excellent stability and even ground pressure.

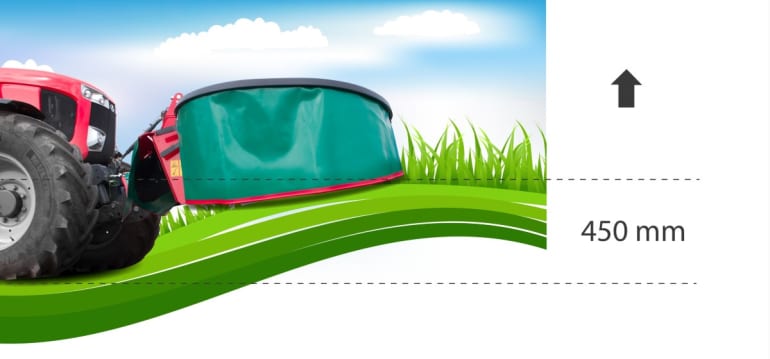

- Flexible adaptation range of 250mm downwards and 420mm upwards.

- Transverse adaptation range of 24º.

- Generous headland clearance of 420mm.

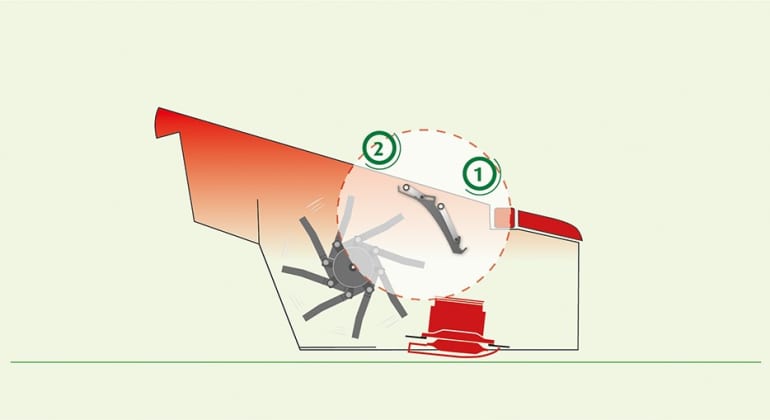

- The Kverneland ProLink suspension concept provides maximum protection of the cutterbar during operation. If hitting a stone or foreign obstacle, a three-fold action takes place simultaneously.

- 1. The cutterbar will move back and up, due to the geometry of the suspension.

- 2. Tension in the ground pressure springs increases, adding additional lift to the mowing section, which helps to clear the obstacle.

- 3. The angle of the cutterbar repositions from 4° downwards to horizontal, for better clearance of the obstacle

- Stubble height adjustment is conveniently integrated directly into the suspension linkage for quick and accurate setting of cutting height.

- There is no need to tilt the A-frame of the tractor

• Kverneland 3300F features a host of new improvements to bring operator comfort to a higher level.

• Easy access to cutterbar for routine maintenance and service inspections. Complete front hood opens to a 90º positon.

• When the front hood is lifted up, it stays in position by a hydraulic damper.

• The complete mower is designed for easy servicing and the low maintenance PTO shaft only requires one seasonal greasing.

• One touch parking handle, to lock and prepare the mower for dismounting.

• The new parking foot is easily activated and keeps the mower in a level position when parked – ready for quick remounting.

- Kverneland 3332 FT and 3336 FT offer dual adjustment of the conditioner plate.

- The conditioner plate can be adjusted at both front and rear ends to provide full adaptability of the conditioner to crop intensity.

- The plate can be set at 5 different positions at the front and 5 different positions at the rear.

- When mowing high and intensive first cut crop you can chose to open up completely at the front and rear end, to allow the massive amount of material to pass through without blockages.

- built-in, guided swath plates are standard.

- Changing from spreading to swathing or adjusting the swath width to crop conditions is done in seconds.

- The swath plates automatically expand when being slid inwards, to support efficient and accurate swathing and there is no need to dismount them to achieve full width spreading.

- Compact design for good overview during transport and operation.

- Even when lifted for transport, the Kverneland 3300F series provides excellent visibility to the front.

- Hydraulic folding of FlexProtect guards are available (optional).

- Kverneland uses round discs. Round discs are less susceptible to stone impact, and reduce shock loads in the transmission.

- Stones are expelled immediately, before they have any chance of becoming jammed. The benefits are lower repair and maintenance costs - at the same time as a clean and aggressive cut.

- The cutterbar has a high oil capacity, ensuring a very low working temperature. This ensures an efficient oil cooling and lubrication of the entire cutterbar.

- The long curved gear wheels running in oil provides a very quiet and reliable power transmission.

- The fully welded cutterbar gives a very stiff and strong design for high durability.

- With the ProFit quick knife change system, maintenance of the cutting ability is easy. The knives are changed by one simple operation using the special lever.

Even More Efficient Conditioning

The new conditioner plate can be adjusted at both front and rear ends to customize the conditioner to crop intensity. The front end is adjusted separately to suit the crop intensity, even for massive crop, to avoid any blockages. Rear end is adjusted to ensure smooth and efficient crop flow into swaths or wide wide spreading.

Steel Tine Conditioner

Utilizing centrifugal force is what makes the Kverneland SemiSwing conditioner stand out among other conditioning systems. It offers an aggressive conditioning effect while still offering excellent tine protection and virtually no wear and tear. During operation tines will stay in a fixed position, providing full conditioning with minimum wear.

Technical specifications

Technical specifications

Download brochure| Model | 3332 FT | 3332 FR | 3336 FT | 3336 FR | |

|---|---|---|---|---|---|

| Conditioner type | SemiSwing | Roller | SemiSwing | Roller | |

| Working width m(ft) | 3.16(10'4") | 3.16(10'4") | 3.60(11'8") | 3.60(11'8") | |

| Transport width m(ft) | 3.00(9'8") | 3.00(9'8") | 3.35(11') | 3.35(11') | |

| PTO (rpm) | 1000 | 1000 | 1000 | 1000 | |

| PTO power req. Min (KW/hp) | 56/75 | 56/75 | 60/80 | 60/80 | |

| Number of discs/knives | 8/16 | 8/16 | 9/18 | 9/18 |

Technical specifications

Technical specifications

Download brochureWorking Width |

No of Discs |

Conditioner |

Power Requirements, Min. |

|

3332 FT |

3.16m |

8 round discs |

SemiSwing Steel tines |

60/80 kW/hp |

3332 FR |

3.16m |

8 round discs |

Roller Conditioning |

60/80 kW/hp |

3336 FT |

3.57m |

9 round discs |

SemiSwing Steel tines |

66/90 kW/hp |

3336 FR |

3.57m |

9 round discs |

Roller Conditioning |

66/90 kW/hp |