Kverneland 53100

Racecar technology for mower conditioners

Triple mower combination with QuattroLink suspension, SemiSwing or roller conditioner, hydraulic adjustment of working width and overlap and optional BX belt. CurvePilot automatic adjustment of overlap standard on 55100 models.

Highlights

Innovative QuattroLink racecar suspension concept ISOBUS - intuitive joystick or terminal control Flexible suspension - 700mm vertical movement Full-width NonStop BreakBack protection Hydraulic adjustment of overlap on the goDescription

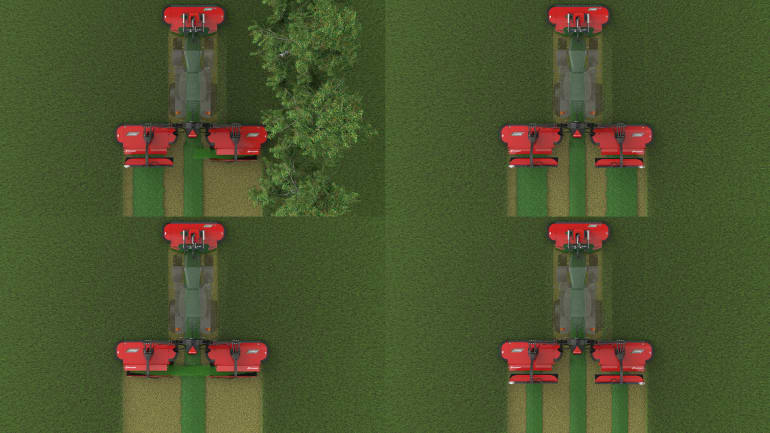

Kverneland 53100 & 55100 Vario models are fully ISOBUS compatible and delivers an outstanding performance with their QuattroLink suspension concept, 10.20m working width and optional BX belt. Unique to the updated version, the 55100, is the added CurvePilot functionality, which automatically adjusts overlap most efficiently between front and rear units when working in curves, giving maximum capacity without leaving stripes in the field. Both models feature with the QuattroLink suspension. Four suspension arms fitted onto a fixed carrying arm that allows the mowing unit to float independently over the field. The optional BX belt automatically does the job of adjusting belt speed to working width, for the same uniform swath width, regardless of position of mowing units.

Highlights

- Innovative QuattroLink racecar suspension concept.

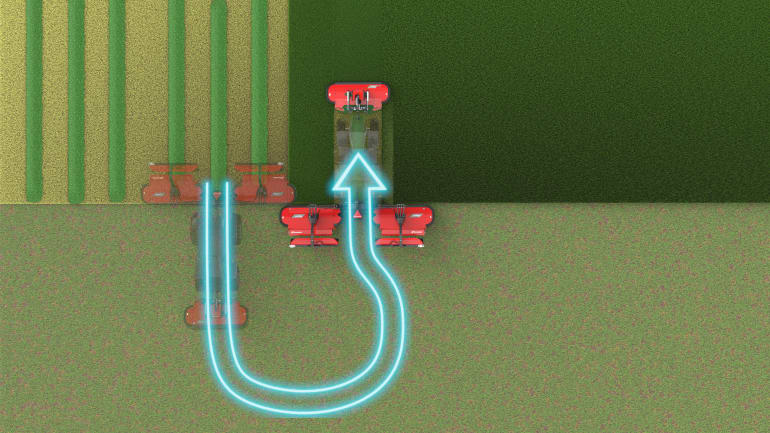

- CurvePilot – Automatic SideShift when working in curves. 55100 models only.

- ISOBUS control with intuitive joystick or terminal control.

- Flexible suspension – 700mm movements, 400mm upwards and 300mm downwards.

- NonStop BreakBack protection across full working width.

- Hydraulic adjustment of overlap on the go.

- Ground pressure remains the same, even when overlap is changed.

- Minimum 500mm ground clearance during headland turns.

- Dual adjustment of conditioner hood - both front and rear end can be adjusted

- Integrated parking feet for vertical storage.

- Automatic belt speed adjustment

- Adjustable belt height

- Belt boost for headland operation

- Autostop function for minimised fuel consumption

- Versatile 4-in-1 solution

Features

Racecar Technology Applied for Mower Conditioners

What makes the QuattroLink suspension unique? The mowing unit is pulled by four suspension arms fitted onto a fixed carrying arm that allows the mowing unit to float independently over the field, adjusting highly accurately and instantly to any changes in ground contours.

No Compromises on Flexibility

The mowing pattern is extremely flexible with a vertical working range of 700mm up and down and a transverse working range of 30°. The 4 arm suspension concept ensures constant ground pressure during working operations.

How You Will Benefit from QuattroLink

Like a race car you want better tracking, ability to go at faster speed and adjust instantly to changing field conditions when operating your mower conditioner. These are the main benefits you will experience when running the kverneland 3300 series and 53100 MT Vario. The four suspension arms provide the mowing unit with an exceptional flexibility in adapting instantly to demanding ground contours inviting for higher speed and more productivity.

Tackle Curves Without Leaving Uncut Crop

CurvePilot is an automatic system, featured on EXTRA 7110, that constantly adjusts overlap between front and rear mowing units so you can utilise the working width and capacity to the maximum.

Full Capacity On Headlands

When mowing headlands you typically position the mowing units with full overlap, reducing working capacity, to avoid leaving uncut crop in the field. With CurvePilot as standard you can mow at full working width and utilise the maximum capacity of the mower. CurvePilot will automatically choose the correct minimum overlap.

Avoid Mistakes During Headland Turns

When mowing A-B lines with a GPS steered solution the tractor can make sudden counter steers when starting again on headlands if you are not hitting the exact starting point of the GPS tracks. When this occurs, CurvePilot immediately increases overlap to compensate and avoid leaving uncut crop behind.

Comfortably Passing Obstacles

When mowing up and down the field you will typically mow with the mowing units at the maximum working capacity, leaving very little overlap between the front and rear mowing units. When driving around obstacles in the field, CurvePilot will automatically adjust the overlap and immediately compensates when you make turns in the field.

Hydraulic Adjustment of Overlap

Kverneland 3336 MT Vario and 53100 MT Vario are fitted with hydraulic SideShift integrated into the carrying arm allowing each mowing units to move 400mm. To easily compensate for changing field conditions, the adjustable overlap is designed as a telescopic arm, directly into the suspension.

Ground Pressure Remains Constant

During mowing operation the carrying arm always remains even to the ground, giving the mowing unit the freedom to instantly compensate and float across uneven ground contours. The true benefit of the suspension concept is that even though overlap is changed, the chosen ground pressure remains the same.

The Kverneland 53100 MT Vario provide generous clearance across the complete cutterbar, including the inside area. When lifting the mower on headlands, the mowing unit is raised and the carrying arm is tilted to a 10° angle. This provides the Kverneland 53100 MT Vario with a level ground clearance of minimum 500mm across the full working width. When lowing the mowing unit the carrying arm is lowered evenly without one side touching the ground before the rest of the mower, avoiding unnecessary stress and wear on the mower

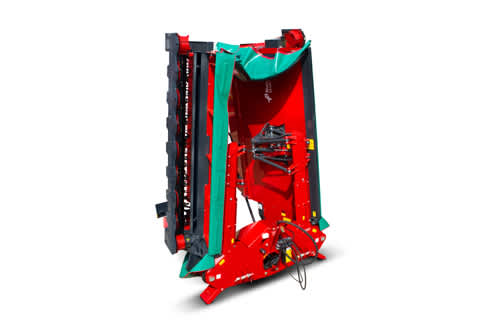

Compact During Transport

The mower folds hydraulically for transport and the telescoping frame arm moves to lowest overlap position, to reach a transport height of only 3.90m. And there is no need to leave the tractor before heading off, the outer FlexProtect protection guard hydraulically folds into transport position.

Parking, Safe and Sure-Footed

With the integrated parking device, storage of the Kverneland 53100 MT Vario is made easy and convenient, requiring a minimum of space during winter storage. The mower is firmly parked on strong and stable parking foot.

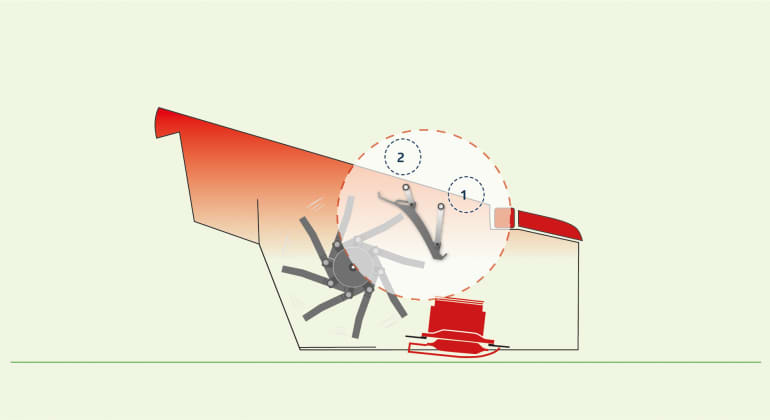

Even More Efficient Conditioning

The new conditioner plate can be adjusted at both front and rear ends to customize the conditioner to crop intensity. The front end is adjusted separately to suit the crop intensity, even for massive crop, to avoid any blockages. Rear end is adjusted to ensure smooth and efficient crop flow into swaths or wide wide spreading.

Steel Tine Conditioner

Utilizing centrifugal force is what makes the Kverneland SemiSwing conditioner stand out among other conditioning systems. It offers an aggressive conditioning effect while still offering excellent tine protection and virtually no wear and tear. During operation tines will stay in a fixed position, providing full conditioning with minimum wear.

Designed for Versatility

The Kverneland BX is primed to maximise working capacity and utilise the full capacity of the 53100 & 55100 without compromising on quality of work. Kverneland BX automatically does the job of adjusting belt speed to working width, for the same uniform swath width, regardless of position of mowing units. This means maximum working capacity, excellent operator comfort and an even, uniform swath formation.

The Advantages

Features all the same advantages as the standard 53100 & 55100 models. Additional advantages include:

- Automatic belt speed adjustment

- Adjustable belt height

- Belt boost for headland operation

- Autostop function for minimised fuel consumption

- Versatile 4-in-1 solution

Our NonStop BreakBack system just got even better. With the new QuattroLink suspension this system now offers protection across the full working width of the mower, including the part closest to the tractor. There are no limiting factors on the inside part of the mower, giving the driver true peace of mind. When hitting an obstacle in the field, the mowing unit will instantly move backwards and up, and then return to the original position.

Even More Efficient Conditioning

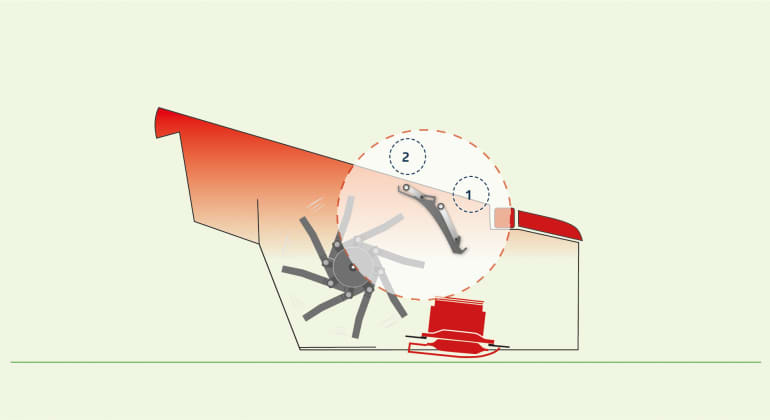

The new conditioner plate can be adjusted at both front and rear ends to customise the conditioner to crop intensity.

The front end (1) is adjusted separately to suit the crop intensity, even for massive crop, to avoid any blockages.

Rear end (2) is adjusted to ensure smooth and efficient crop flow into swaths or widespreading.

Precision Farming

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

IsoMatch Tellus GO+ is especially developed for controlling the machine in a simple way. The farmer is in full control of the machine in exactly the way he wants. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch. Controlling the implement has never been so easy.

This can be you your first step into Precision Farming

IsoMatch Tellus GO+ makes it easy to control any ISOBUS machine from your tractor cab. IsoMatch GEOCONTROL enables you to achieve higher yields, lower costs and do your work with less hassle. This licence key is divided in two parts, Section Control and Variable Rate Control, which are available from the IsoMatch Shop. Now you can buy the specific functionality that you need.

Technical specifications

Technical specifications

Download brochure| Model | 53100 MT | 53100 MT BX | 53100 MR | 53100 MR BX | 55100 MT | 55100 MT BX | 55100 MR | 55100 MR BX | |

|---|---|---|---|---|---|---|---|---|---|

| Conditioner type | SemiSwing | SemiSwing | Roller | Roller | SemiSwing | SemiSwing | Roller | Roller | |

| Working width m(ft) | 9.80/10.20 (32’2”/33’5”) | 9.80/10.20 (32’2”/33’5”) | 9.80/10.20 (32’2”/33’5”) | 9.80/10.20 (32’2”/33’5”) | 9.80/10.20 (32’2”/33’5”) | 9.80/10.20 (32’2”/33’5”) | 9.80/10.20 (32’2”/33’5”) | 9.80/10.20 (32’2”/33’5”) | |

| Transport width m(ft) | 2.90(9'6") | 2.90(9'6") | 2.90(9'6") | 2.90(9'6") | 2.90(9'6") | 2.90(9'6") | 2.90(9'6") | 2.90(9'6") | |

| PTO (rpm) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | |

| PTO power req. min (kW/hp) | 150/200 | 175/240 | 150/200 | 175/240 | 150/200 | 175/240 | 150/200 | 175/240 | |

| Number of discs/knives | 2x9/2x18 | 2x9/2x18 | 2x9/2x18 | 2x9/2x18 | 2x9/2x18 | 2x9/2x18 | 2x9/2x18 | 2x9/2x18 |

Technical specifications

Technical specifications

Download brochureWorking Width |

Number of Discs |

Conditioner |

|

53100 MT Vario |

9.80-10.20m |

2 x 9 discs |

SemiSwing Steel Tine Conditioner |

53100 MR Vario |

9.80-10.20m |

2 x 9 discs |

Roller Conditioner |